PopStar 21

Designing the PopStar 21

Every so often, when strolling along the Swan River margins, in Perth, Western Australia, where I live, I keep wandering what type of craft would suit best for gunkholing those placid waters. In my way of thinking this boat had to be versatile, capable of exploring the many havens along the margins, had to be simple to assemble and disassemble to save time in getting ready to start sailing, had to be trailerable, so it could be kept at home and be taken to different places, and last but not least, be fun to sail, either for enjoying a day-sail with family or friends, or experiencing the thrill of high performance when having a competitive crew onboard.

The Pop Star 21 is a simple and versatile boat that will provide lots of fun for the crew.

Talking to friends we learned that heaps of people from different places are craving for a craft like that, to sail in coastal or protected waters, like bays, lakes and rivers. However, it was when an Argentinean friend of ours told us that he had the intention of developing a new class with exactly those characteristics that we decided the time had come to develop a design like that.

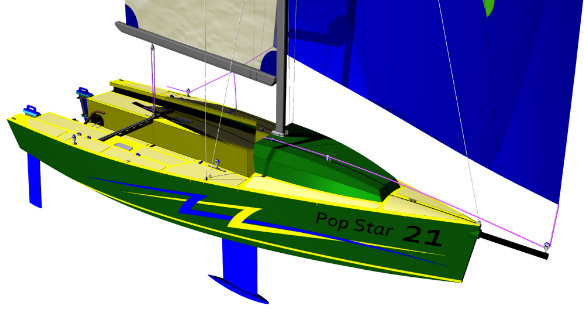

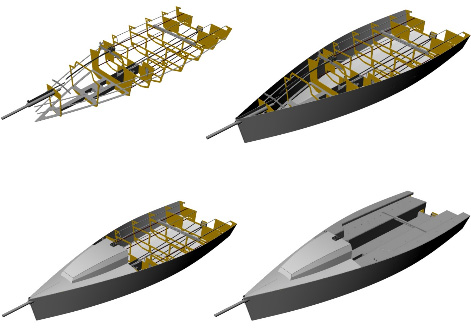

We began designing a modern multichine hull with flat bottom and wide stern, following the lines of our most recent sailboats, the Pop 25 and the Pop Alu 32, having an almost vertical bow and sharp angled forward waterlines, so to cut the seas effortlessly, the dead-rise aft being very smooth to reduce drag and facilitate planing. For easiness of construction the hull was designed with five panels only, the bottom one being flat transversally, two topsides with very short flair, and two small bilge panels.

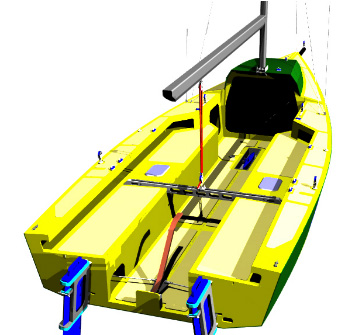

The superstructure has a cuddy cabin in front of the mast, intended mainly to store sails and equipment while not in use, but with enough space to be used as a bunk to rest on when wished. The most valuable part of the deck is the cockpit, which goes from the cabin entrance at the mast section to the transom. There are two seats at a lower level, these seats being more comfortable when sailing leisurely, and two higher ones at sheer level for the crew to sit and hike in heavy winds, to be used when trying to achieve the highest performance possible.

The superstructure has a cuddy cabin in front of the mast and lots of space in the cockpit.

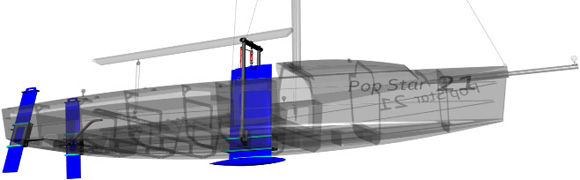

The keel weighs 110kg with 85% of this weight at the bulb, so to increase stability and efficiency without increasing the overall weight of the boat. It can be lifted to reduce draught to simplify the operation of launching and retrieving the boat from the water using the trailer. The lifting device is removable and when it is not being used, it can be stored inside the cabin not to mess up the crew circulation on the cockpit while sailing.

We chose to install twin rudders to improve manoeuvrability and steering control even in the hardest conditions. The rudder blades can also be lifted to reduce the boat’s draught.

The rudders and keel can be lifted to simplify the operation in the slipway to reduce the draught.

The sail plan has a large mainsail, a 110% fractional jib and a gennaker, this one hoisted from the tip of a retractable bowsprit. For those who prefer relaxed sailing there is the option of using a mainsail of less roach and smaller area, and to suppress the gennaker. The mast has one pair of spreaders and can be pivoted on its base to be lowered when passing under bridges. This is done by removing a single pin, and it can also be taken off for transport or storage.

The sail plan has a large mainsail, a jib and an asymmetric spinnaker hoisted from the tip of a retractable bowsprit.

When sailing in shallow depth areas, as when exploring rivulets or regions where sailing is not possible, we designed the tiller base fitting with a bracket for a low power outboard motor.

The construction method is welded aluminium and all pieces can be cut by CNC. The files containing the drawings of all pieces are provided together with the stock plan. After receiving all these pieces already cut to millimetric precision anyone with minimum experience in aluminium welding can assemble the hull and perform all the welding in just a few weeks working on spare time only.

The assembly sequence is simple and straight forward.

Regarding our friend in Argentina who kicked our arses to develop this design, he has already started the construction of the first Pop Star 21 and has the metal work almost completed. He is thinking of a series that might be up to ten boats, which will be one of the main summer attractions of a resort he is building in the beautiful region of Cordoda, sailing on the waters of a lake surrounded by mountains. He sent some construction photos that can be seen in the in the specific page of the Pop Star 21 in our website. He also sent the video below showing the first boat almost completed.