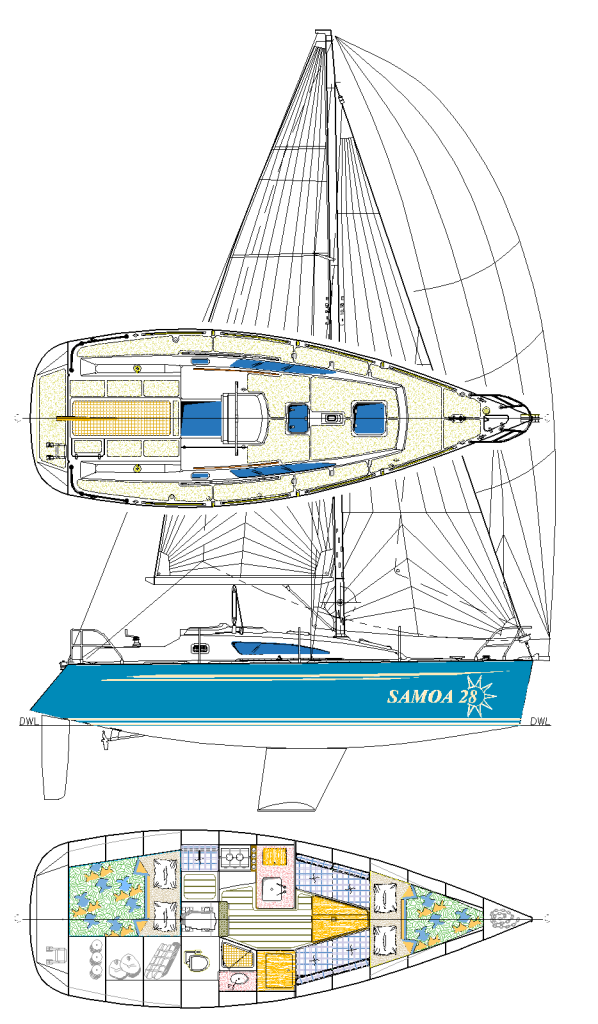

The Samoa 28 is a cruiser-racer specified for sandwich construction that can be built by professionals or amateur builders. The result is a good performance sailboat that is comfortable and beautiful.

To bring the process of construction within the reach of the inexperienced amateur builder, we defined for this boat the construction method called strip-planking sandwich. The result is a light and strong hull. This is ideal for the construction of one single unit, with minimum waste on the usually expensive moulds needed for fiberglass construction.

The deck layout is designed for easy handling and the rigging is well suited for cruising with a robust mast design and no running backstays.

But the Samoa 28 is a wolf in a sheepskin. Its lightness, together with a generous sail area and a very efficient bulbous fin-keel configuration, makes her a competitive racing yacht in club regattas. With her modern silhouette and her equal aptitudes for cruising and club racing, the Samoa 28 is destined to be a club highlight.

Technical Data

Length Overall

8.80 m (28’ 11”)

Length Waterline

7.56 m (24’ 9”)

Beam

3.12 m (10’ 3”)

Draft (cruising/racing)

1.50/1.70 m (4’ 11”/ 5’ 7”)

Ballast

1,075 kg (3,355 lbs)

Displacement

3,000 kg (6,600 lbs)

Fresh water capacity

340 l (90 gal)

Diesel capacity

100 l (26 gal)

Standing Headroom

1.85 m (6’ 1”)

Sail Area

35.3 m2 (380 sq. ft)

Auxiliary Propulsion

14 hp

Construction

Fiberglass sandwich

List of Plans

SM28 – S0A – Full Size Patterns A

SM28 – S0B – Full Size Patterns B

SM28 – S0C – Full Size Patterns C

SM28 – S0D – Full Size Patterns D

SM28 – S0E – Full Size Patterns E

SM28 – S0F – Full Size Patterns F

SM28 – S0G – Rudder Full Size

SM28 – S1 – Lines Plan

SM28 – S2 – Mast and Sails

SM28 – S2B – Mast and Sails B

SM28 – S3 – Interior Layout

SM28 – S4A – Deck Layout

SM28 – S5A – Structural Plan

SM28 – S6A – Transverse Sections A

SM28 – S6B – Transverse Sections B

SM28 – S6C – Bulkhead Cut-outs

SM28 – S7A – Cruising Keel

SM28 – S7B – Performance Keel

SM28 – S7C – Steel Case Keel

SM28 – S8 – Rudder

SM28 – S8B – Rudder Wheel Steering

SM28 – S8C – Quadrant

SM28 – S9 – Custom Fittings

SM28 – S10 – Hatch

SM28 – S11 – Engine Installation

SM28 – S12 – Stem

SM28 – S13 – Propeller Strut

Boat Description

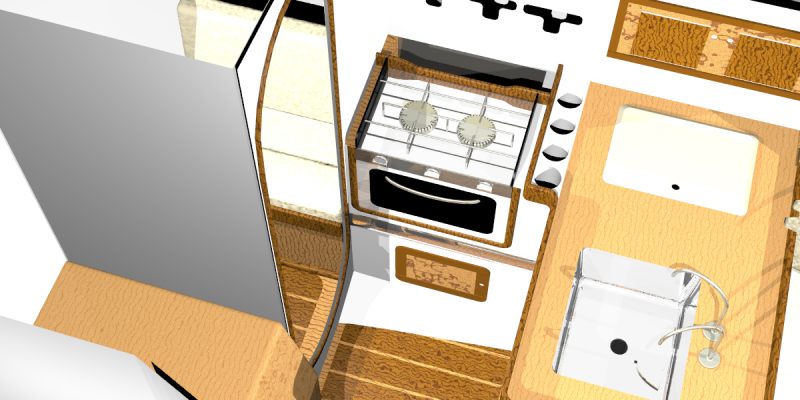

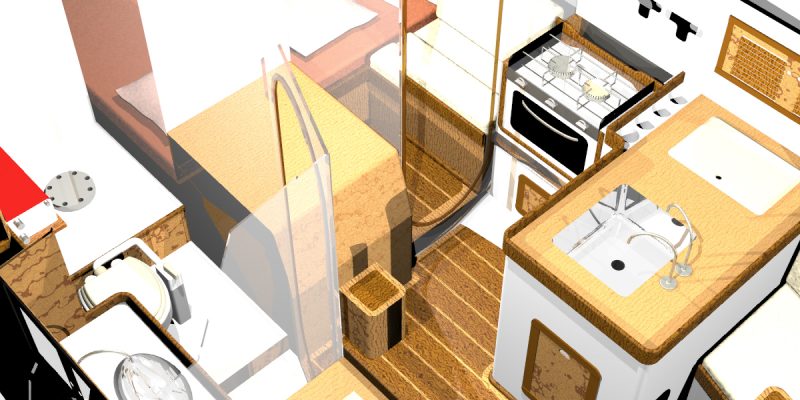

The layout is suitable for long stretched living onboard. A double berth is placed forward, going from the anchor chain locker bulkhead to the seats of the dinette. The saloon is comfortable enough for four persons to have a meal on the folding table attached to the mast pillar, or six adults to be entertained in this social area. The galley and the navigation station are placed at the boat’s mid-section, an area of maximum beam and better ventilation. The owner’s cabin is placed at the aft quarters with a double berth, clothes lockers, and a sofa to portside, and at starboard is located the head. Abaft the head there is a large bin to store sails and other boat gear. The gas locker is located at the starboard aft corner of the cockpit and is only accessible by means of a lazarette hatch inserted in the cockpit seat. Any eventual gas leakage is drained through a scupper opening on to the transom wall.

Above decks the Samoa 28 is an easy boat to be handled. The traveller, placed in front of the companionway hatch, doesn’t interfere with the dodger, an important feature when cruising. The cabin trunk extending to the fore deck gives more headroom inside and provides the crew with a foothold when going to the fore deck.

We opted for a 15/16-rigg to provide maximum safety when cruising, employing two pairs of swept back spreaders with single lowers. This configuration gives plenty of rigidity to the mast, the larger genoa and spinnaker compensating for a lack of mast flexibility. On the other hand, when cruising, the rigid mast provides peace of mind and safety.

The hull is specified for strip-planking sandwich construction. This method consists of building the hull with strips of light wood or PVC foam over temporary moulds. This “planking” is covered with fibreglass reinforced with epoxy resin and then sanded and plastered in preparation for painting. After turning the hull upside, the moulds are removed and an internal fibreglass lamination is also applied over the bare interior. Next the structure and divisions are installed, the furniture is completed, and finally the superstructure is built. If P.V.C. foam is the choice for hull construction, the deck should also be built with this material, otherwise, use marine plywood covered with fibreglass. The completed boat is light and strong, and all phases of construction are of simple execution.

Browse Gallery

See Related Plans