This is one of our most popular designs, with dozens of boats build by amateur and professional builders, in several different countries. Many builders and owners have lived onboard and travelled around the world with lots of comfort, safety and minimum maintenance costs.

The plans for the Multichine 28 are extremely detailed what allows people with no previous construction experience to build an ocean-going cruising boat without difficulties. Simplicity of construction is a highlight of the Multichine 28 design. The final product is an exceptional blue water cruising sailboat.

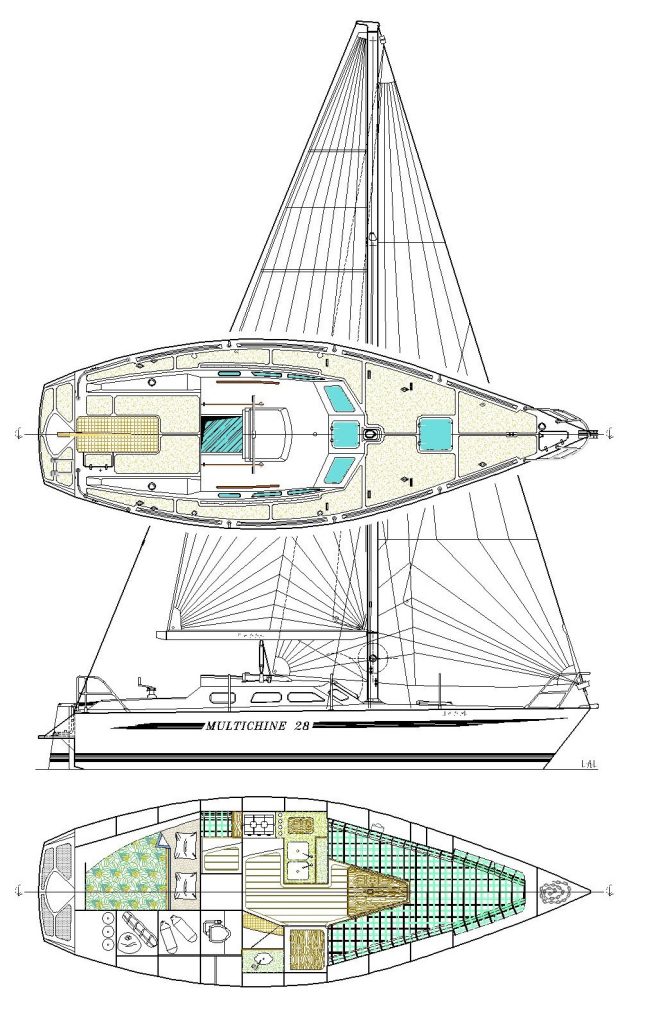

The rigging layout is simple and easy to sail. The sail plan is suitable for heavy weather sailing and the interior layout is practical and safe for comfortable living, even when the weather outside is not at its best.

Technical Data

Length Overall

9.20 m (30’ 2”)

Length Waterline

7.82 m (25’ 6”)

Beam

3.18 m (10’ 5”)

Draft

1.52 m (4’ 11”)

Ballast

1,200 kg (2,643 lbs)

Displacement

3,580 kg (7,885 lbs)

Fresh water capacity

420 l (110 gal)

Diesel capacity

120 l (32 gal)

Standing Headroom

1.85 m

Rig Type

Sloop

Sail Area (short mast)

35.62 m2 (283 sq. ft)

Sail Area (long mast)

40.24 m2 (433 sq. ft)

Auxiliary Propulsion

21 hp

Construction

Plyglass

List of Plans

Building Manual

MC28- S0A – Full Size Patterns A

MC28- S0B – Full Size Patterns B

MC28- S0C – Full Size Patterns C

MC28- S0D – Full Size Patterns D

MC28- S0E – Full Size Patterns E

MC28- S0F – Full Size Patterns F

MC28- S0G – Stem Full Size Pattern

MC28- S1 – Lines Plan

MC28- S2A – Mast and Sails (short mast)

MC28-S2B – Mast and Sails (long mast)

MC28- S3 – Interior Layout

MC28- S4 – Deck Layout

MC28- S5 – Structural Arrangement

MC28- S6A – Transversal Sections

MC28- S6B – Plywood Cutting

MC28- S7A – Keel

MC28- S7B – Steel Box Keel

MC28- S7C – Lead Keel

MC28- S8 – Transom Platform

MC28- S9A – Custom Fittings

MC28- S9B – Pushpit

MC28- S9C – Transom Arch

MC28- S10 – Companionway Hatch

MC28- S11 – Engine and Propulsion

The Multichine 28 stock plan includes a building manual with a comprehensive description of all phases of the construction, besides supplying general information concerning boat building employing the plywood/epoxy building method. This building manual is an important factor in assisting the inexperienced builder in obtaining a high standard of construction all along the building process.

This manual was written during the building of two boats of the class, the Multichine 28 Makai and Fiu. During construction we tested the tips related in the text on those very successful boats, giving us a high degree certainty about the accuracy of the information contained in the manual.

Boat Description

The Multichine 28 design maximises the internal space. The internal living area extends from anchor well bulkhead to transom. The result is a very comfortable boat for it’s size and cost.

The aft cabin with its private hall, exclusive settee, a profusion of lockers and a large double berth offers the comfort of a stateroom (i.e. the captain’s cabin).

Over the aft cabin, the cockpit design has an unusually large deck bridge under which allows one to sit comfortably on the aft bunk without touching the headliner, what gives an unequalled sensation of spaciousness. An opening portlight in the transom, and another at the cabin trunk sidewall provide good illumination and air circulation even if the cabin door is shut. The cockpit side and front walls are also adequate for the installation of other opening ports too, if wished.

The fact that one can walk with 1.85m headroom from the aft cabin to the main saloon, contouring one of the amplest galleys to be found in twenty-eight footers is something the Multichine 28 owners highly appreciate.

To starboard, opposite to the galley, is installed a very spacious head with room for a vanity unit with sink, shower and toilet. Abaft the head there is a large compartment for storage of bulkier equipment, such as inflatable dinghy, awning, sails, etc. At the aft end, a gas locker draining through the transom is the only compartment with direct access to the cockpit.

An integrated fuel tank is placed just abaft the toilet and is only a few centimetres higher than the toilet sole. Over the tank cover there is place for a sewage holding tank, still leaving a corridor for stowing long items, like paddles, outboard motor for the dinghy and so on.

The L shaped galley, besides being jumbo sized, also allows the cook to stay out of the traffic from the companionway hatch. Two sinks, icebox, stove and ample locker space ensures comfortable onboard living conditions while in the marina or during extended cruises.

Still on starboard there is an ample navigation quarter where the navigator will sit facing aft, using the back part of the dinette couch.

The dinette is V shaped and surrounds the dining table. Forward there is another double berth that extends up to the collision bulkhead.

When required, a curtain separates this fore berth from the dinette, allowing the usage of the table area without disturbing those using the berth. This fore compartment is served by a hatch on the deck above, a necessary convenience, particularly in nice weather, when the hatch may be kept open for maximum ventilation.

Another outstanding feature of the MC28 is its tanks capacity. She carries 420 litres of fresh water in three integrated tanks and 120 litres of fuel, what provides large navigation autonomy. The fuel tanks being integrated to the hull are leak-proof and are practically immune to condensation, a desirable feature for protection against water contamination of the fuel due to water vapour condensation.

Outside, the Multichine 28 is designed to be functional and easy to build. With a small cabin trunk and a flush, unobstructed fore deck, there is sufficient room in front of the cabin for a solid dinghy to be stowed.

The cockpit is large enough to be used in warm nights as an extra double berth, provided that the cockpit grating is lifted to the level of the seats, and cushions or sleeping bags available for this purpose are extended over the area. The traveller, placed on top of the coach-roof, keeps the cockpit uncluttered, significantly enhancing its comfort. The dodger, when installed (we strongly advise to do so), does not interfere with the mainsail sheet, and the sheet control is easily accessed even by the helmsman, since the sheet tail is at a short distance from the tiller.

The boarding platform aft, with its swimming ladder, is quite handy, still serving as a bumper in case of collision from abaft.

Another practical solution, a trade mark of the design, is its vertical transom, with its externally hinged rudder. The simplicity and low cost of this arrangement fits nicely with the purpose of ultimate simplicity of the design.

When defining the characteristics of the project we decided that above all other things the MC28 had to be an open sea cruising sailboat. So, we did not provide any direct access from the cockpit to the interior except if the owner wishes to install an opening port on the portside cockpit sidewall. The compartment under the starboard cockpit seat is the gas locker, which is separated from the interior by a tight wall.

The Dinghy Caravela 1.7 was designed custom made for the MC28 flush foredeck. You can download the plans for free in our website. Some of our clients built the dinghy before they built the boat willing to get acquainted with the plywood/epoxy building technique, common to both crafts. Since the cost of building this dinghy is insignificant and the fact that it will be a good option for the boat tender, we advise building it as a preliminary training.

The MC28 is a mast top sloop with one pair of spreaders and two pairs of lower shrouds. This is by far the simplest and most reliable rig configuration.

The design also contemplates an optional sail plan with larger sail area and a taller mast with two pairs of spreaders. This plan is intended for those who wish more speed in light winds and are happy to put on a reef earlier when the weather gets rough.

The Multichine 28 construction system is the result of a long experience acquired in the application of the most reliable building technique for amateur construction, the so-called plywood/epoxy building method. Plywood is an easy to find, dimensionally stable and extremely strong material for its weight, and when its surface is saturated with epoxy resin, it lasts for many decades without showing the least signal of aging.

Saturating internally and sheathing the outside of the boat with fiberglass saturated with epoxy, the durability of the boat is indefinite, since the first boats designed by our office built according to these specifications, after more than thirty years of usage are still in excellent state of conservation.

Our approach to the construction of the Multichine 28 is of emphasizing the pre-fabrication of the transverse structure that provides the boat’s framing and shape. These structural components consist of bulkheads, or semi-bulkheads, strategically located at full stations.

They should be built to the most advanced stage of construction possible before taking them to assemblage. This is important, in our opinion, because if these pieces, which are quite easy to be produced, are correctly built, the remaining of the work represents very little difficulty.

That is the main reason, we reckon, that so many amateurs have successfully concluded the constructions of their Multichine 28, even if they didn’t have the slightest previous experience in boat building.

The construction of the Multichine 28 follows a logical sequence, not intending to provide shortcuts that in our way of thinking are only illusory, like, for instance, the stitch and glue building method for larger yachts, which we do not consider advantageous.

We substitute the expensive epoxy filleting along the internal edges of the chines for wooden clamps, easy to be installed and costing peanuts if compared to the large amount of the so expensive epoxy necessary to accomplish the same function. What we call an illusory feeling is the sensation of having a hull assembled in a fortnight, remaining everything else to be done later, in a much more awkward position and with considerably more difficulty to proceed with the work.

The time to sheath the structure with plywood according to our method is the same or perhaps smaller than to assemble if stitching and gluing, with the advantage that you work on a solid foundation.

Browse Gallery

See Related Plans